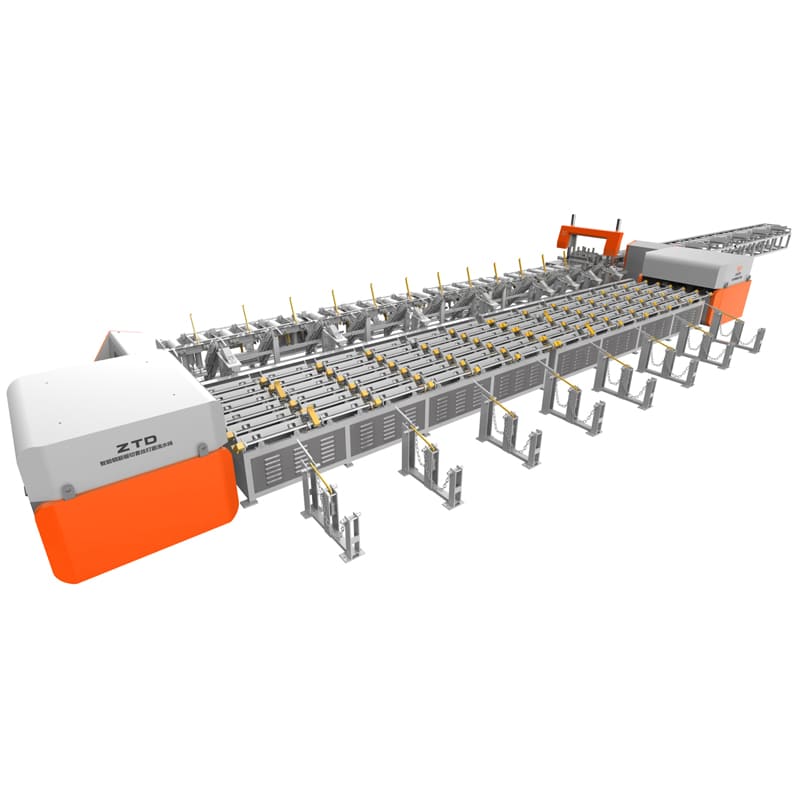

Steel Bar Cutting Threading Line

Steel Bar Cutting Threading Line is engineered for superior efficiency and precision in steel bar processing. Designed to process one steel bar with two threaded ends in just 12 seconds, this advanced system enables the completion of up to 4,000 thread ends during an 8-hour shift, handling over 100 tons of steel bar thread rolling daily.

Key Features:

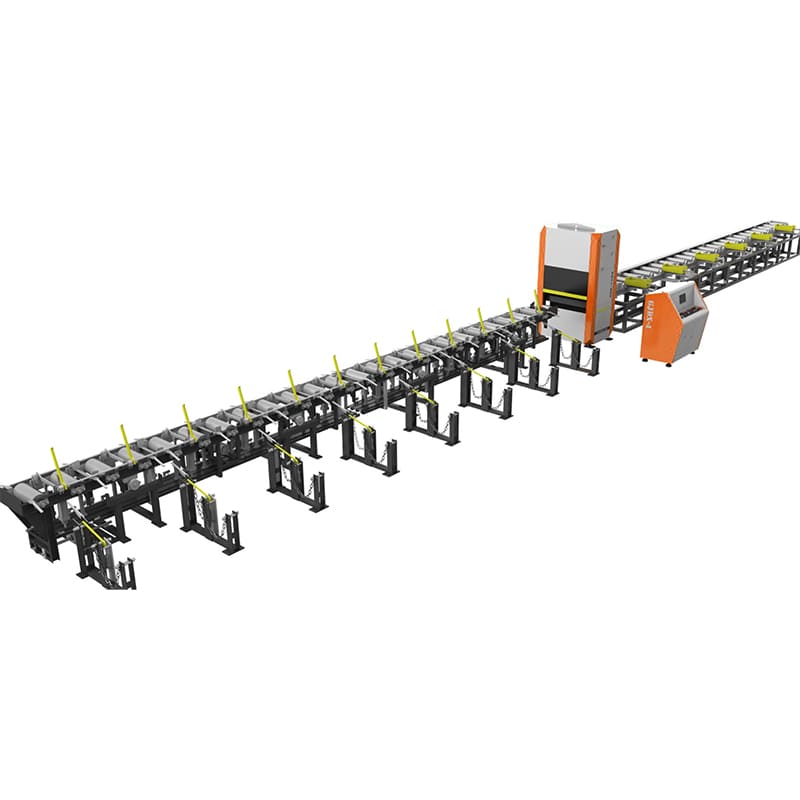

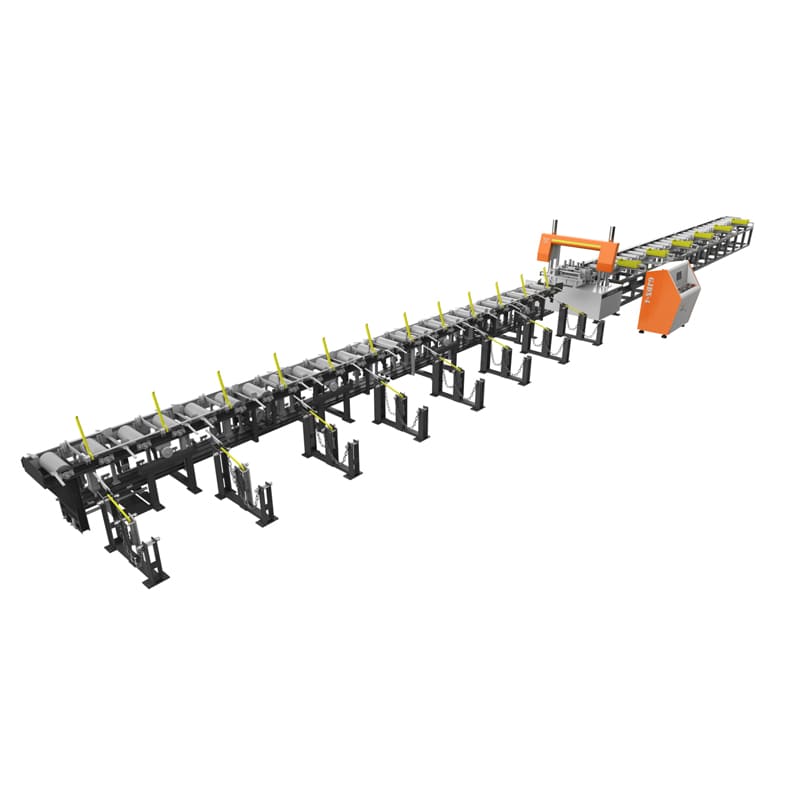

- High-Speed Cutting: Capable of cutting steel bars ranging from 700mm to 12,000mm in length with a cutting speed of 30 pieces per minute.

- Precise Cuts: Achieves millimeter-level accuracy (±5mm), ensuring high precision in every operation.

- Versatile Threading: Handles bar diameters from φ10mm to φ40mm, with an ability to process different threading sizes accurately.

- Efficient Power Usage: Operates with a total power of 57.5KW, making it energy-efficient for large-scale production.

- Modular and Compact Design: With a space requirement of just 26m x 4.5m, it is ideal for installations in smaller or confined spaces.

Specifications:

| Feature | Specification |

|---|---|

| Feed Speed (m/min) | 40-60 |

| Cut Length (mm) | 700-12,000 |

| Cut Tolerance (mm) | ±5 |

| Cut Speed (time/min) | 30 |

| Blade Width (mm) | 260 |

| Mini Cut Length (Manual) | 10 |

| Mini Cut Length (Automatic) | 700 |

| Bar Diameter (mm) | φ10-40 |

| Power (kw) | 57.5KW |

| Machine Size (L x W x H, mm) | 26,000 x 4,500 x 1,500 |

Advantages:

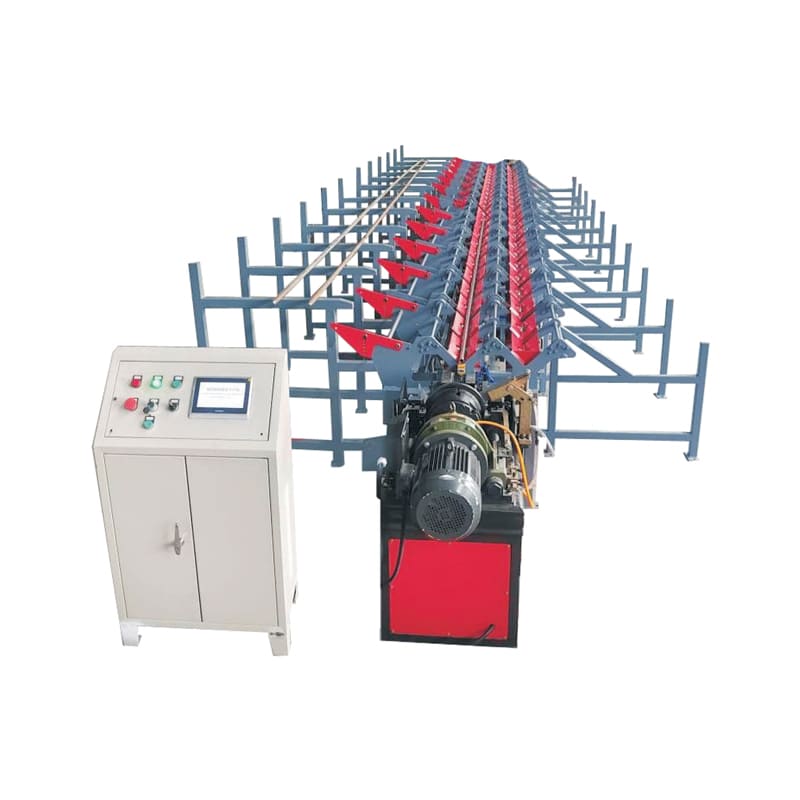

- Cutting-Edge Technology: The line features rib stripping and thread rolling size induction technology to ensure high-quality threads and minimal defects.

- Low Operating Costs: Tools cost less than 0.2 yuan each and are designed to last over a month, minimizing operational expenses.

- Centralized Control: PLC control system and integrated sensors ensure smooth operation and prevent defects, offering greater reliability.

- Compact Footprint: Requires only 10m x 16m of space, making it highly efficient for space-constrained environments.

- Versatile and Modular: Easy to transport and set up, adapting seamlessly to various steel bar threading requirements.

Performance and Efficiency:

- Production Capacity: Capable of processing thousands of thread ends daily with high-speed and accurate operations.

- Quality Assurance: Provides cuts and threads with precision to within 1mm, ensuring top-notch quality and consistency.

Steel Bar Threading Equipment and Grinding Production Line is the ideal solution for high-volume steel bar processing, offering outstanding productivity, minimal defects, and cost-effective operation. Maximize your production efficiency and quality with this advanced system.