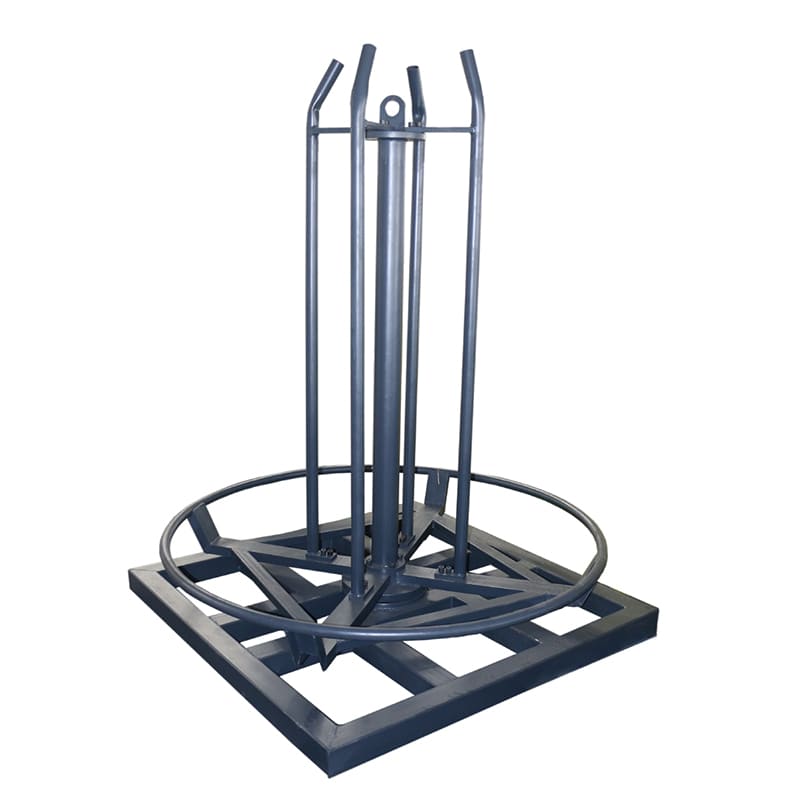

Steel Bar Coil Rotating Pay-off Stand

A rotating pay-off stand (or coil cradle) is a material-handling device used to store and dispense coiled reinforcement bars (rebar) in construction sites, steel processing workshops, and fabrication plants. It ensures smooth unwinding, reduces manual labor, and minimizes tangling.

1. Key Components

(1) Rotating Frame

-

Structure: Steel-welded central shaft, support arms, and base.

-

Types:

-

Vertical Type (common, space-efficient).

-

Horizontal Type (for limited spaces).

-

-

Rotation: 360° free-spinning with bearings or bushings for low friction.

(2) Coil Support Platform

-

Load Capacity: Typically 1–5 tons (adjustable for Φ6mm–Φ16mm rebar coils).

-

Surface: Rubber-lined or with rollers to prevent abrasion.

(3) Braking System (Optional)

-

Manual brake or automatic damping to control unwinding speed and prevent over-spinning.

(4) Mobile Base (Optional)

-

Equipped with locking casters for easy relocation.

2. Design Considerations

(1) Load & Stability

-

Center of gravity: Must align with the rotational axis to avoid tipping.

-

Base reinforcement: Wider footprint or weighted base for heavy coils.

(2) Smooth Rotation

-

Anti-friction: Use sealed bearings (e.g., tapered roller bearings) instead of plain shafts.

-

Avoid excessive free-spin (risk of entanglement).

(3) Safety Features

-

Guard shields over rotating parts (OSHA/CE compliance).

-

Anti-springback bars to prevent recoil injuries.

3. Operational Guidelines

(1) Loading the Coil

-

Use a crane or forklift to center the coil on the stand.

-

Secure the coil’s inner ring to prevent slippage.

(2) Unwinding Process

-

Pull rebar evenly at a 5°–10° angle to the coil’s tangent.

-

Wear gloves and stand clear of the rotating frame.

(3) Maintenance

-

Lubricate bearings monthly (grease recommended).

-

Inspect for structural cracks or rust damage.