CNC Simple Steel Bar Threading Line

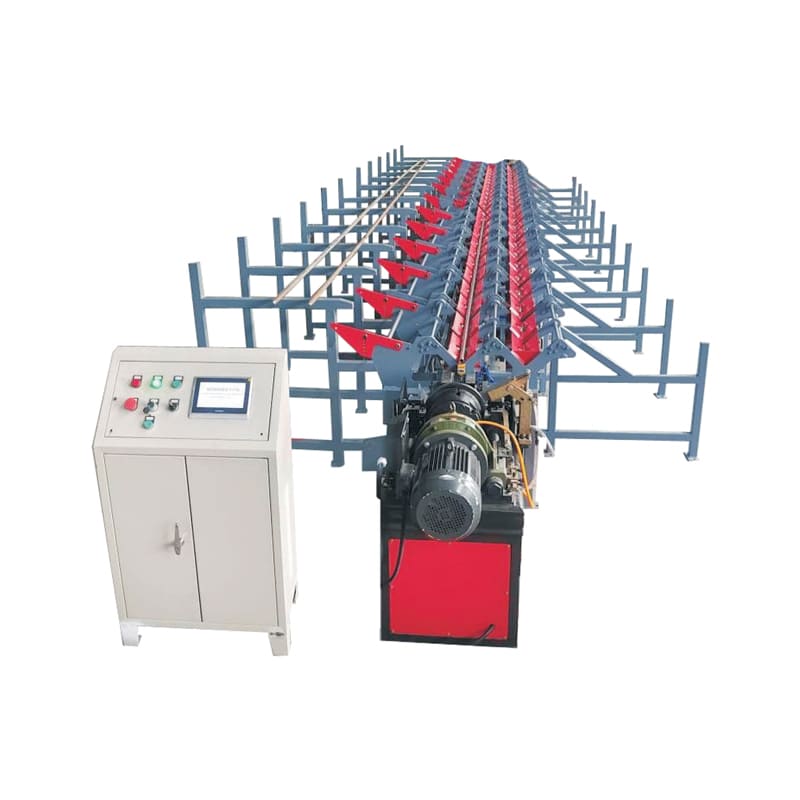

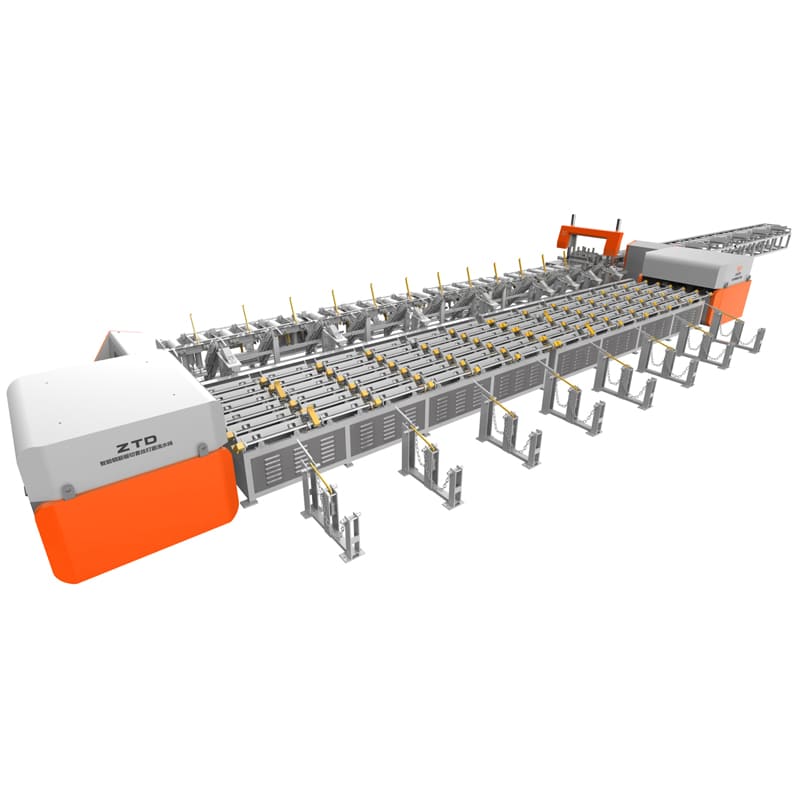

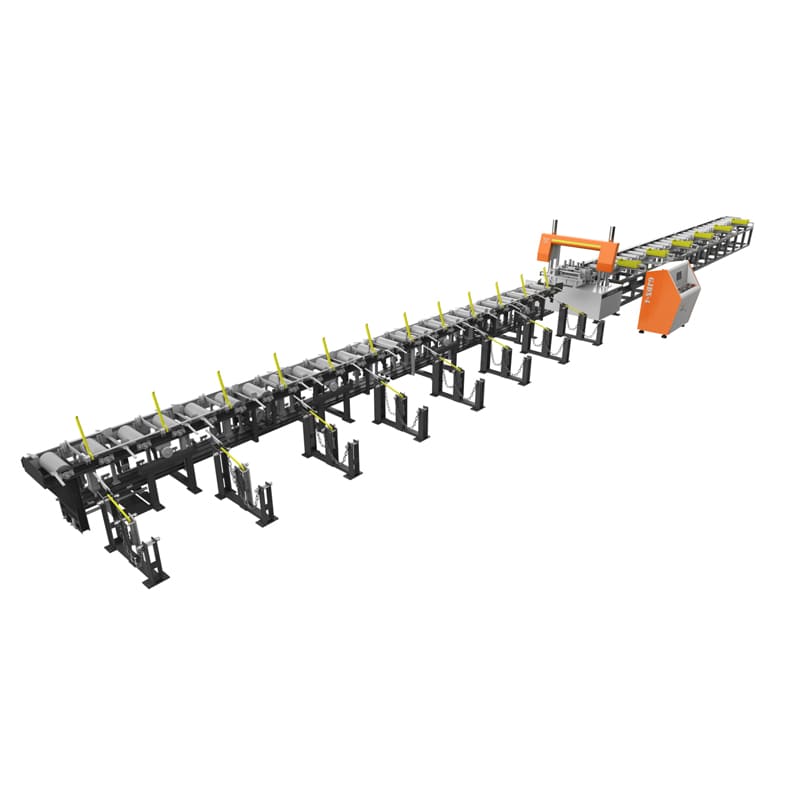

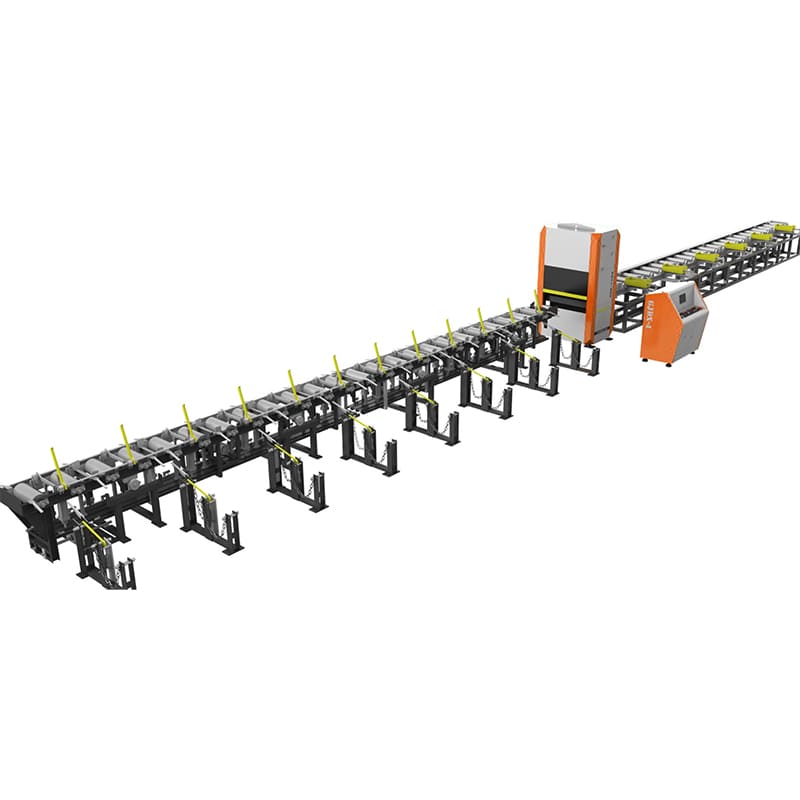

CNC Simple Steel Bar Threading Line is a cutting-edge solution designed to optimize steel bar processing with high precision and efficiency. This advanced system includes essential components such as a material preparation rack, a feeding platform, two threading machines, a storage platform, and a digitally controlled electric cabinet for seamless automation.

Threading Line Specifications:

| Feature | Specification |

|---|---|

| Rebar Diameter (mm) | Φ16~Φ40 |

| Rebar Length (m) | 2-12m |

| End Length (mm) | 80mm |

| Rebar Feed Speed | 22m/min |

| Total Power | 22kw |

| Threading Motor | 7.5kw*2 |

| Power Consumption | 8KW/H |

| Size | 1300030001300mm |

Threading Line Key Features and Benefits:

- Automated Efficiency

The CNC threading line supports steel bars with diameters from 16mm to 50mm and strength grades such as HRB335, HRB400, and HRB500. It uses a combination of electrical, hydraulic, and pneumatic technologies for fast, reliable performance with minimal manual intervention, ensuring high output. - Advanced Material Handling

Equipped with a large storage rack and automatic bar feeding platform, this system minimizes manual handling. Durable, quiet V-shaped rollers ensure smooth operation, and the main processing head automatically handles clamping, feeding, diameter reduction, and thread rolling for consistent, high-quality results. - High Production Capacity

The line can process up to 1,000 wire heads and handle 400 to 500 steel bars in a 10-hour shift, making it perfect for large-scale projects with tight deadlines, without sacrificing precision.

Conclusion:

CNC Simple Steel Bar Threading Line is an efficient and high-capacity solution for steel bar processing. With advanced automation, low maintenance, and superior productivity, it’s an ideal choice for construction and industrial applications requiring fast and precise threading.