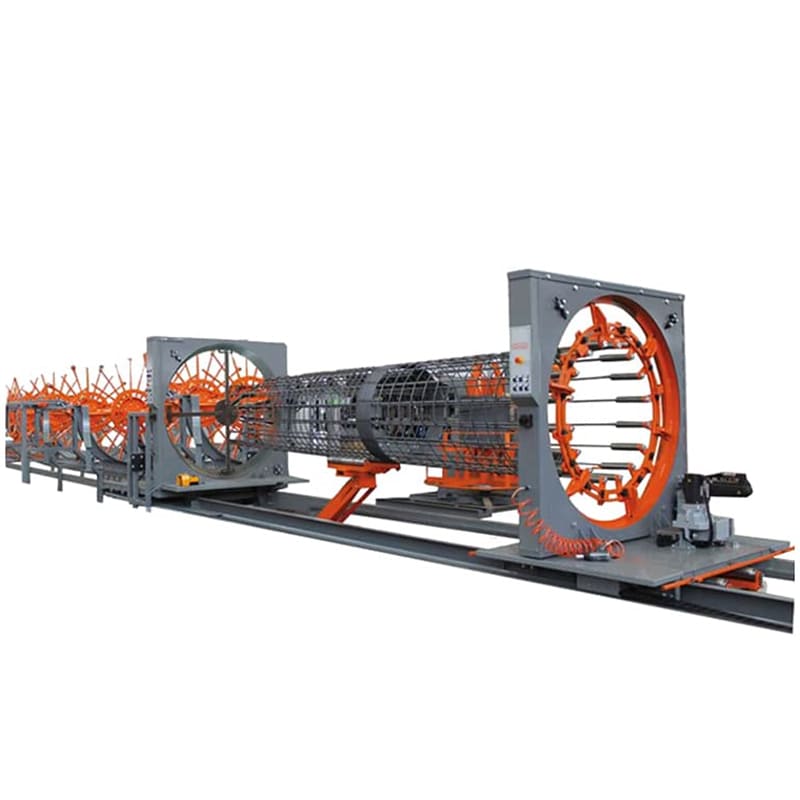

Pile Cage Making Machine Overview

Pile Cage Making Machine is a PLC-controlled system engineered to automate and simplify the production of rebar cages. By replacing the traditional manual binding process, this machine significantly enhances efficiency, making it ideal for large-scale projects such as bridges and high-speed rail construction.

Cage Machine Technical Parameters

| Parameter | ZHL-1500 | ZHL-2000-12 |

|---|---|---|

| Cage Diameter (mm) | 300–1500 | 600–2000 |

| Cage Length (mm) | Customized (≥12m) | Customized (≥12m) |

| Cage Weight (kg) | 4500 | 6000 |

| Main Frame Bar Diameter (mm) | φ12–32 | φ12–32 |

| Coil Bar Diameter (mm) | φ6–16 | φ6–12 |

| Coil Bar Distance (mm) | 50–400 | 50–400 |

| Welding Way | Carbon-dioxide arc welding | Carbon-dioxide arc welding |

| Voltage | 380V 50Hz/Customized | 380V 50Hz/Customized |

| Power (kW) | 13 | 23 |

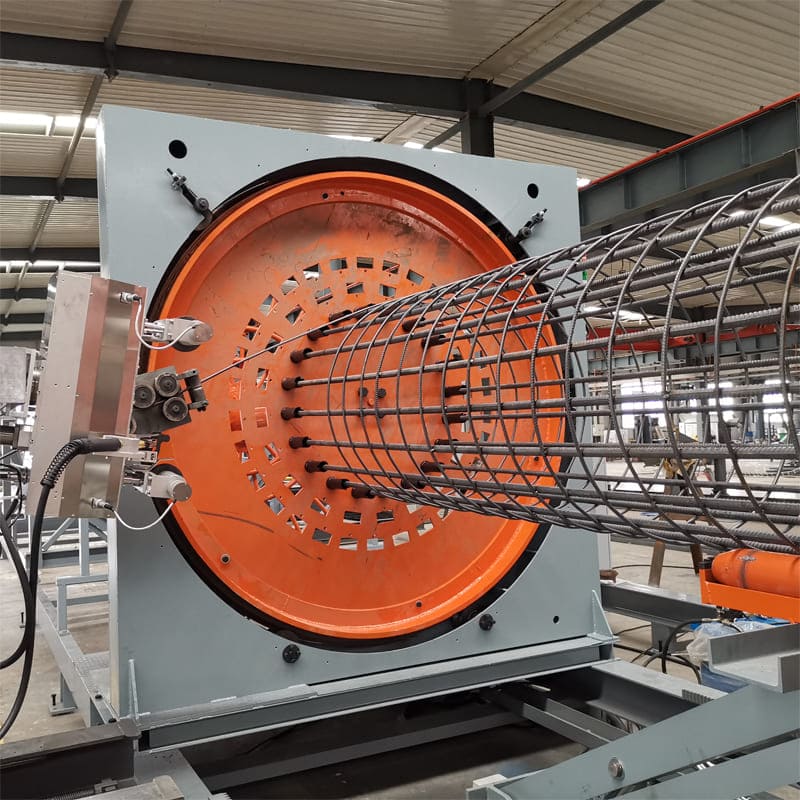

Machine Work Principle

The operator inserts the main rebar into specific holes on the fixed and mobile rotating disks. Coiled reinforcement (wrap) is welded to the main rebar, and as the disks rotate, the wrap winds around the main bars while being welded. This automated process ensures:

- Precise spacing between stirrups and main bars.

- Uniform cage diameters.

- High-quality products meeting construction standards without constant supervision.

Key Features

- Fast and Efficient Production:

A team of 10 workers, operating in two shifts, can produce over 20 fully completed, 12-meter-long rebar cages in a day. - High Precision and Consistency:

The CNC control system ensures uniform spacing and consistent cage diameters, reducing the need for frequent inspections. - Cost and Labor Savings:

Mechanized processing reduces material usage by 1.5% compared to manual methods, eliminates overlapping stirrups, and minimizes labor costs. - Streamlined Workflow:

The machine simplifies overlapping multiple cages, saving time during hoisting and assembly.

Benefits of Mechanized Processing

- Faster Production:

The high-speed operation is perfect for large-scale projects, significantly reducing production time. - Improved Quality Control:

CNC automation ensures precise and consistent results, meeting strict industry standards. - Reduced Supervision:

Automation reduces the need for frequent inspections, saving time and resources. - Material Efficiency:

Eliminating overlapping stirrups minimizes waste, lowering overall construction costs.

This machine is an indispensable asset for construction projects requiring high-quality rebar cages with enhanced speed and precision.