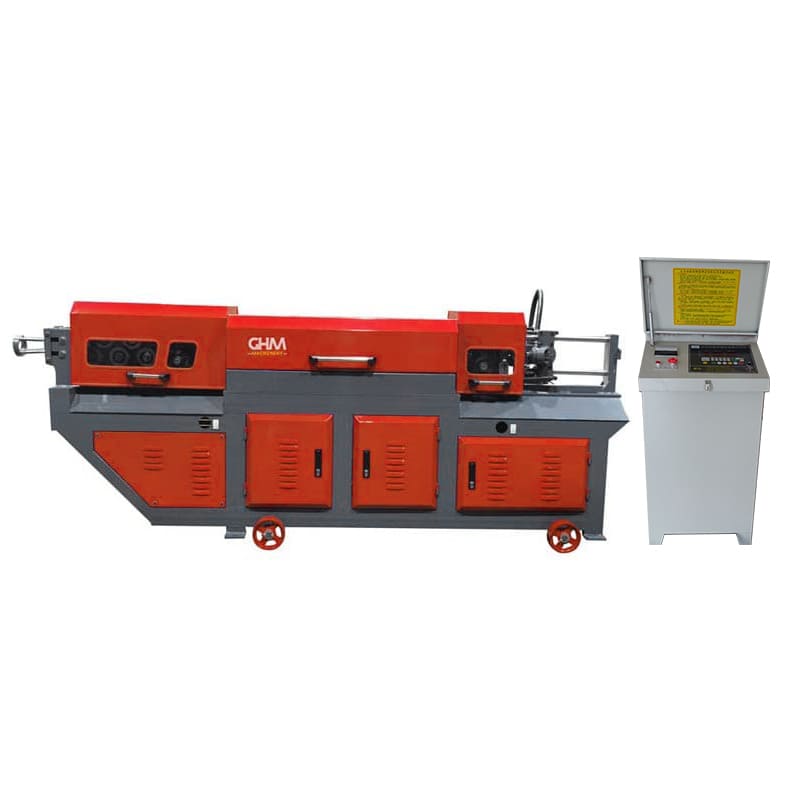

GT2-4 High-Speed Rebar Straightening and Cutting Machine

GT2-4 High-Speed Rebar Straightening and Cutting Machine is designed for fast, precise, and highly efficient metal wire processing. With an advanced PLC control system, this machine delivers exceptional accuracy, minimal cutting errors, and high-speed operation, making it ideal for various applications in hardware manufacturing, construction, and industrial production.

Technical Specifications

| Model | GT2-4 |

|---|---|

| Wire Capacity | ø2mm – ø4mm |

| Cutting Length | Up to 9999mm |

| Cutting Accuracy | ±1mm |

| Processing Speed | 100m/min |

| Servo Straightening & Traction Motor | 3 kW + 3.8 kW |

| Servo Motor | 2.6 kW |

| Straightening Accuracy | ±1mm/m |

| Weight | 1000 kg |

| Control System | PLC |

| Voltage Options | 380V (customizable) |

Key Applications

Industrial and Hardware Production

- Pet cages, chicken cages

- Air conditioning mesh covers

- Bicycle baskets and spokes

- Umbrella stands, bird cages

- Refrigerator shelves, wire baskets

- Construction wires, wire mesh screens

Compatible Wire Types

- Stainless steel

- Cold-drawn wire

- Galvanized wire

- Iron wire

- Steel wire

- Aluminum wire

- Water pumping wire

- Steel bars

Operating Principle

- High-Speed Operation:

The machine’s motor drives a belt that rotates the straightening cylinder at high speed, straightening the metal wire and removing any surface rust with the help of a straightening die. - Precision Feeding and Cutting:

Two transmission rollers, powered by the motor and gear reducers, feed the wire forward. These rollers also drive a crank wheel that moves the hammer head up and down, ensuring precise cutting cycles. - Cutting Cycle:

As the wire reaches the desired length, the hammer head strikes the upper tool holder, cutting the wire. The cut pieces then fall into a receiving rack. Once the cutting cycle is complete, the tool holder returns to its original position, ready for the next cycle.

Why Choose the GT2-4 High-Speed Rebar Straightening and Cutting Machine?

With high-speed processing, minimal cutting errors, and precision control, the GT2-4 is the perfect solution for high-volume wire production. Whether you need to process rebar or other metal wires in various industries, this machine ensures reliable, accurate results with low maintenance and easy operation.