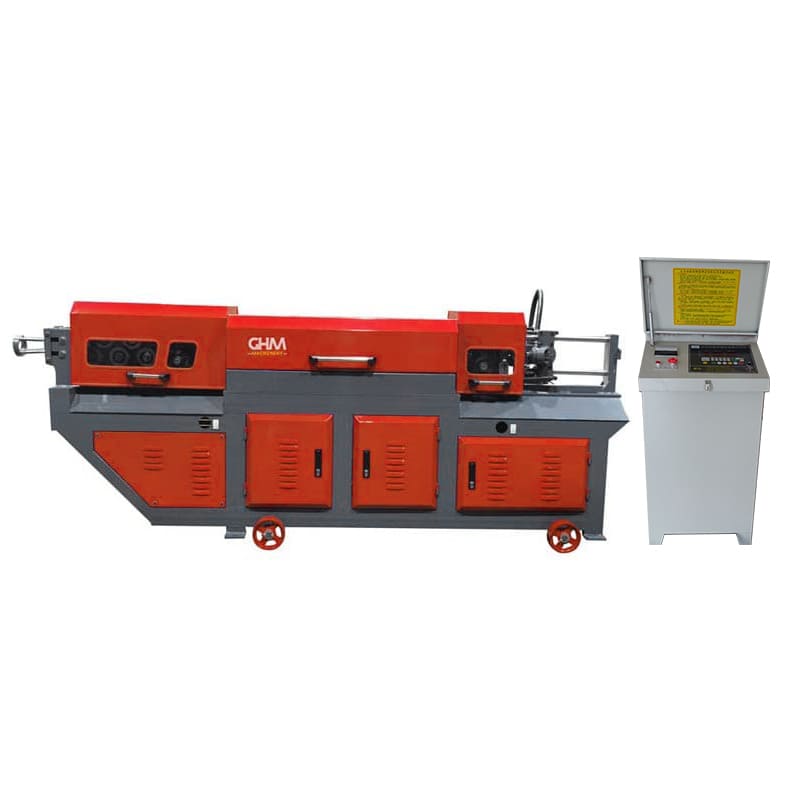

Purposes and Characteristics of the GT6-14 Steel Bar Straightening Cutting Machine

GT6-14 Steel Bar Straightening Cutting Machine is an advanced tool designed to straighten and cut various types of steel bars, including cold-rolled Level III steel, plain round bars, and hot-rolled coiled round steel. Its precision and efficiency make it a crucial asset for construction and industries requiring reliable steel processing.

GT6-14 Machine Key Features and Benefits

- High Automation and Speed: The machine operates with a fully automated system, offering fast pulling speeds and continuous operation for maximum productivity.

- Precision Processing: Delivers smooth, scratch-free steel surfaces with minimal strength loss, ensuring excellent straightness and accuracy.

- User-Friendly Design: Simplified operation with an intuitive blanking process enhances user convenience and boosts production efficiency.

- Safety and Reliability: Features an automatic counting and shutdown device, ensuring secure and reliable operation.

Technical Specifications

| Parameter | Details |

|---|---|

| Capacity | II Rebar (≤450N): Ø5mm-Ø14mm |

| III Rebar (≤650N): Ø5mm-Ø12mm | |

| Cutting Length | 300mm and above |

| Cutting Error | ±0.5cm |

| Speed | 55-85 m/min |

| Straighten & Traction Motor | 15 kW |

| Pump Motor | 5.5 kW |

| Voltage | 380V (customizable) |

| Straightening Accuracy | ±2mm/m |

| Weight | 1,200 kg |

| Dimensions (L×W×H) | 3500×1070×1280 mm |

Structure and Performance

The GT6-14 consists of:

- Traction Straightening Unit: Features adjustable straightening wheels for precision alignment.

- Hydraulic Cutting System: Delivers precise cuts powered by hydraulics, ideal for larger diameters and tougher materials.

- Blanking Frame: Ensures orderly handling of processed materials.

- Electric Control Cabinet: Simplifies operations with intuitive controls and safety features.

Application Areas

GT6-14 Steel Bar Straightening Cutting Machine is ideal for:

- Construction: Used for rebar straightening and cutting in infrastructure projects.

- Hardware Production: Manufactures products like cages, building meshes, and other steel-based items.

- Handicrafts: Processes steel for intricate and precise designs.

With its high-speed operation, minimal errors, and efficient performance, the GT6-14 Rebar Straightening and Cutting Machine is a dependable choice for industries needing consistent and accurate steel processing.