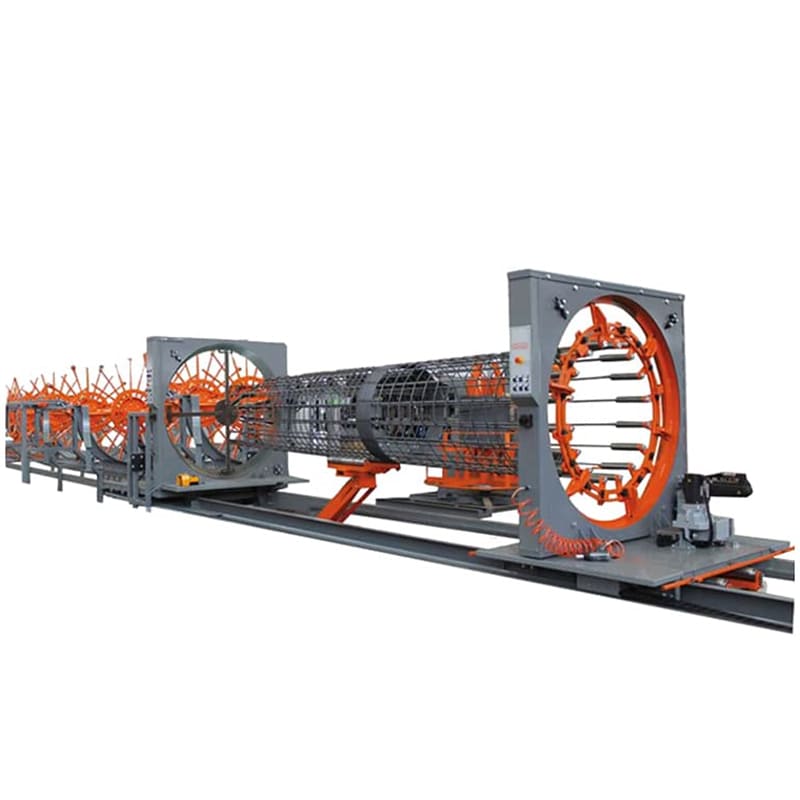

GHJ-3000 Steel Pile Cage Winding Machine

GHJ-3000 Steel Pile Cage Winding Machine is designed for the efficient and precise winding of rebar cages, primarily used in large-scale engineering concrete structures such as high-rise buildings, highways, high-speed railways, and large bridges. This machine is ideal for bending and processing main skeleton steel bars, providing enhanced productivity and consistent quality for construction projects.

Technical Specifications

| Model | GHJ-3000 Steel Pile Cage Winding Machine |

|---|---|

| Cage Diameter | Φ600 – Φ3000mm |

| Cage Length | Up to 30m (customizable) |

| Winding Speed | 0 – 15.4m/min |

| Car Speed | 0 – 1.38m/min |

| Iron Bar Motor | Y90l-4, 4 kW |

| Trolley Motor | Y90l-4, 4 kW |

| Total Weight | 4500 kg |

| Main Machine Dimensions | 13 * 1.8 * 0.8m |

| Trolley Dimensions | 15 * 1.3 * 1.5m |

Key Features

Numerical Control Technology:

- Ensures stable winding speed, uniform spacing, and consistent quality throughout the operation.

Modular Design:

- Easy to disassemble, move, and transport each component, making it convenient for different project sites.

Customizable Cage Specifications:

- The diameter and length of the rebar cage can be adjusted, allowing for flexibility in meeting the requirements of various projects.

Easy Operation and Labor Savings:

- Simple operation with minimal training required for workers. A team of 2-3 people can efficiently operate the equipment, saving on labor costs.

Low Power Consumption:

- The machine’s total power consumption is under 10kW, making it energy-efficient while delivering high performance.

Dual Control Functions:

- The electric control box and remote control offer flexible and convenient dual control, allowing for precise operation from a distance.

Synchronized Winding and Memory Function:

- The trolley can synchronize two winding ribs, and the host machine has a memory function to store and adjust operating parameters for future use.

Cost-Effective:

- The machine ensures tight stirrup formation without overlap, saving up to 15% of materials compared to manual winding methods, reducing overall construction costs.

Why Choose GHJ-3000 Steel Pile Cage Winding Machine?

GHJ-3000 Steel Pile Cage Winding Machine is an essential tool for high-efficiency steel bar cage winding, offering customizable configurations and reliable performance. Whether you’re working on massive infrastructure projects or large-scale concrete structures, this machine streamlines operations, reduces labor costs, and ensures consistent high-quality results every time.